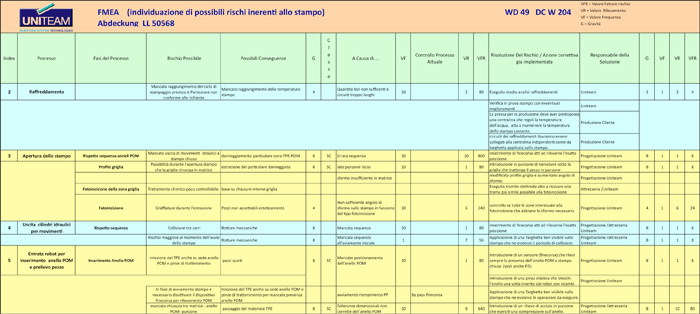

The FMEA analysis imply the accurate verification of all the choices made during the design phase about materials, geometry, checking systems, tolerances and all other aspects influencing the tool functionality, reliability and safety. Through this cross-functional activity with the design, R&D, and quality departments, the FMEA analysis, intended as a defect prevention tool, allows a gap optimisation between the design and the manufacturing phases and a flexibility and reliability increase.

CONTROL AND ANALYSIS METHODS

FMEA (Risk Analysis)

Moldflow (F+P+W+C)

The part is accurately analysed with Filling, Packing, Warpage and Cooling simulations; thus enabling to design a mould to fully comply with aesthetical, dimensional and structural requirements and with a further focus on cycle time reduction, and moulding window widening.

Our Mold Flow Package includes also ICM (Injection-Compression Moulding); GIM (Gas Injection Moulding); and Mucell analysis.

Dimensional Controls

For dimensional controls of parts or the mould itself the most advanced instruments are used (optic-scanners, lasers ...). Our objective is to give the customer a dimensional report according to his specs of assembly and product functionality.

Dimensional controls can be carried out during the tool trial with portable devices or by certified measuring facilities.